Robust I2C slave without a sampling clock

25 Aug 2011

Updated 2 May 2020

I2C is a popular two-wire serial bus protocol for communicating between devices. Most MCUs support it, so it’s a good choice of interface for many chips. This article shows how to implement an I2C slave interface without the use of a bus sampling clock.

Bus sampling is a simple way to implement an I2C slave, but in order to support reasonable I2C transfer rates, you need a sampling clock frequency of several MHz. This is fine if the rest of your device already needs such a fast clock, but if it doesn’t, then power consumption is needlessly increased. A robust I2C slave can be implemented using nothing but the bus signals for clocking. This has the advantage that the slave interface consumes no power (save for leakage currents) when the bus is idle.

The scheme described here can support any bus speed and is highly reliable. It’s compatible with multi-master buses, and doesn’t require the master support delayed acknowledgement or clock-stretching.

Overview of the I2C protocol

The I2C bus consists of two lines: SCL (serial clock)

and SDA (serial data), both of which are normally held at

logic high via a weak pull-up resistor. Devices control the bus by

choosing to pull lines to logic low, or leaving their outputs

high-impedance. This is the basic mechanism behind multi-master

arbitration, but this won’t be covered here – for simplicity, we’ll

assume a single master with multiple slaves.

There are three special events generated by the master, called

START, STOP and RESTART. These

are used, respectively, to being a transaction, end a transaction, and

start a new transaction without releasing control of the bus. Timing

diagrams for these three events are shown here:

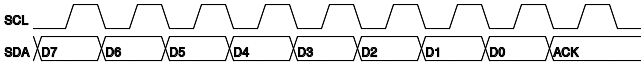

There are two types of byte transfer events: master-to-slave and slave-to-master. The timing for both is the same:

Data bits are placed on SDA MSB-first. In a

master-to-slave transaction, the master clocks out a data byte over the

first 8 cycles, and then the slave acknowledges on the 9th cycle by

pulling SDA low. A slave-to-master transaction is exactly

the reverse, except that the master only acknowledges if it wishes the

slave to transmit another byte. Without this rule, the slave might

continue to pull SDA down for the next cycle, preventing

the master from being able to generate a RESTART or a

STOP event.

The master controls SCL (except in the case of clock

stretching, which isn’t covered here). SDA may only change

while SCL is low, except when the master is generating a

START/RESTART/STOP event.

Transaction structure

All transactions begin, after a START or

RESTART event, with a master-to-slave transfer containing

an address byte. The upper 7 bits of the address byte are the slave

address, and the LSB is the R/W# bit, which signifies the

direction of the following transfers (low for master-to-slave, high for

slave-to-master). If the slave address is recognised by a device on the

bus, it acknowledges on the 9th SCL pulse by pulling

SDA low. Other devices must ignore the remainder of the

transaction. The transaction ends with a RESTART or

STOP event.

Typical use

Most slave devices have a number of indexed internal registers. The way I2C is usually used to manipulate the internal registers of such devices is described here. To write a register, the master initiates a write transaction to the desired device. The register index is transferred following the device address, and then the desired data. For example, to write 0x57 to register 3 of device 1010101x, the following sequence of events occurs:

STARTMaster-to-slave: device address,

R/W#= 0 (0xAA)Master-to-slave: register index (0x03)

Master-to-slave: register data (0x57)

STOP

Read transactions are slightly more complex. Since I2C transactions

are unidirectional, two transactions are needed, divided by a

RESTART. The first (write transaction) sends the register

index to the device, and the value is sent in the next transaction

(read). For example, to read back the value written in the previous

example, the following sequence of bus events occurs:

STARTMaster-to-slave: device address,

R/W#= 0 (0xAA)Master-to-slave: register index (0x03)

RESTARTMaster-to-slave: device address,

R/W#= 1 (0xAB)Slave-to-master (not acked): register data (0x57)

STOP

Two conventions are usually adopted to make this system more convenient:

The internal register index is incremented after each transfer. This allows efficient bulk transfer of a block of data to/from logically contiguous registers.

The internal register index is reset to 0 following a

STARTevent (but notRESTART). Typically, register 0 is a status register, so this allows efficient polling of the status register with a single I2C transaction.

The implementation described in this article follows this conventional scheme.

Implementation

For this implementation, we will assume an asynchronous reset input,

though this won’t be shown in circuit diagrams. There is an

SCL input, and a tri-state SDA port. Other

interfaces are not covered explicitly.

The flip-flops will be driven mostly by SCL. Input data

latching must be done on the rising edge, as this is the only time we

can guarantee stable data. Conversely, output latching must be done on

the falling edge of SCL. Internal logic may operate on any

edge, but here we use the falling edge consistently.

START/STOP/RESTART

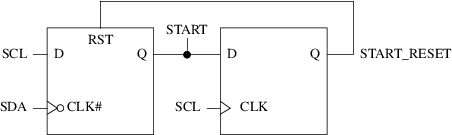

First, we need to be able to detect a START event. The

following pair of flip-flops will do that:

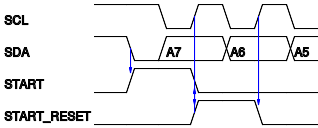

This generates a pulse lasting from the START event

itself to the next rise of SCL (covering exactly one

falling edge) as shown in the timing diagram:

The Verilog implementation of this is:

reg start_detect;

reg start_resetter;

wire start_rst = RST | start_resetter;

always @ (posedge start_rst or negedge SDA)

begin

if (start_rst)

start_detect <= 1'b0;

else

start_detect <= SCL;

end

always @ (posedge RST or posedge SCL)

begin

if (RST)

start_resetter <= 1'b0;

else

start_resetter <= start_detect;

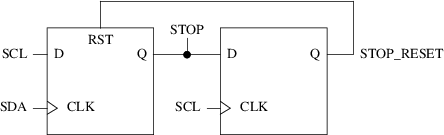

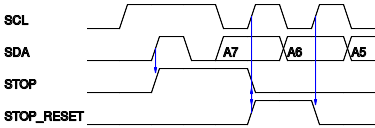

endThe STOP detector is similar, except for the sense of

the SDA clock input:

It generates a pulse from the STOP event to the next

rise of SCL, again covering exactly one fall of SCL in the

next transaction:

The Verilog implementation is:

reg stop_detect;

reg stop_resetter;

wire stop_rst = RST | stop_resetter;

always @ (posedge stop_rst or posedge SDA)

begin

if (stop_rst)

stop_detect <= 1'b0;

else

stop_detect <= SCL;

end

always @ (posedge RST or posedge SCL)

begin

if (RST)

stop_resetter <= 1'b0;

else

stop_resetter <= stop_detect;

endGiven these two detectors, we don’t need to implement a

RESTART detector – we can distinguish between a

START and a RESTART by checking to see if a

STOP event has occured prior to the

START/RESTART. Of course, the first

START after reset will be misinterpreted as a

RESTART, but in practice this doesn’t matter, since we will

reset the index pointer on reset anyway.

Latching input data

To keep track of what stage a transfer is in, we need a modulo-9

counter. It needs to be triggered on the falling edge of SCL, so that it

can reset with START events:

reg [3:0] bit_counter;

wire lsb_bit = (bit_counter == 4'h7) && !start_detect;

wire ack_bit = (bit_counter == 4'h8) && !start_detect;

always @ (negedge SCL)

begin

if (ack_bit || start_detect)

bit_counter <= 4'h0;

else

bit_counter <= bit_counter + 4'h1;

endWe need to latch data bits into a shift register as they appear:

reg [7:0] input_shift;

parameter [6:0] device_address = 7'h55;

wire address_detect = (input_shift[7:1] == device_address);

wire read_write_bit = input_shift[0];

always @ (posedge SCL)

if (!ack_bit)

input_shift <= {input_shift[6:0], SDA};Not shifting on the ACK bit means that the data is complete and

stable for two clock cycles, which is useful later. Note that since the

data is shifted on the positive edge of SCL, we have a

complete data byte for two falling edges of SCL – once with

lsb_bit high, and once with ack_bit high. We

need a separate means of detecting acknowledgement during a

slave-to-master transfer:

reg master_ack;

always @ (posedge SCL)

if (ack_bit)

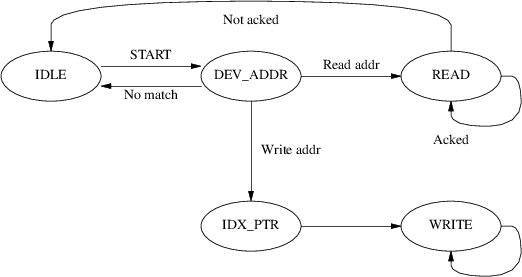

master_ack <= ~SDA;State machine

Having constructed input handling logic, we can now use it to control a state machine. This machine’s states remain stable over an entire transfer, changing at the boundary between transfers, or between transfers and special events. The state transition diagram is:

The occurance of a START condition acts as a state

machine synchronous reset:

parameter [2:0] STATE_IDLE = 3'h0,

STATE_DEV_ADDR = 3'h1,

STATE_READ = 3'h2,

STATE_IDX_PTR = 3'h3,

STATE_WRITE = 3'h4;

reg [2:0] state;

wire write_strobe = (state == STATE_WRITE) && ack_bit;

always @ (posedge RST or negedge SCL)

begin

if (RST)

state <= STATE_IDLE;

else if (start_detect)

state <= STATE_DEV_ADDR;

else if (ack_bit)

begin

case (state)

STATE_IDLE:

state <= STATE_IDLE;

STATE_DEV_ADDR:

if (!address_detect)

state <= STATE_IDLE;

else if (read_write_bit)

state <= STATE_READ;

else

state <= STATE_IDX_PTR;

STATE_READ:

if (master_ack)

state <= STATE_READ;

else

state <= STATE_IDLE;

STATE_IDX_PTR:

state <= STATE_WRITE;

STATE_WRITE:

state <= STATE_WRITE;

endcase

end

endRegister transfers

Before handling register transfers, we need to maintain the state of

the index pointer. This index is loaded by the first transfer in a write

transaction, incremented every other transfer, and reset on a

START condition (but not RESTART). It is

implemented as follows:

always @ (posedge RST or negedge SCL)

begin

if (RST)

index_pointer <= 8'h00;

else if (stop_detect)

index_pointer <= 8'h00;

else if (ack_bit)

begin

if (state == STATE_IDX_PTR)

index_pointer <= input_shift;

else

index_pointer <= index_pointer + 8'h01;

end

endHandling register writes is straight-forward. For each register, once per transfer, we check to see if it’s being addressed for writing, and if so, we latch the value in the input shift register. For example, to handle writes to a register that has index 0x03:

reg [7:0] reg_03;

always @ (posedge RST or negedge SCL)

begin

if (RST)

reg_03 <= 8'h00;

else if (write_strobe && (index_pointer == 8'h03))

reg_03 <= input_shift;

endTo handle read requests, it’s most convenient internally to deal with byte transfers. In order to do this, we need an output shift register. It must be loaded before the ACK bit, in order to be ready for the output stage:

reg [7:0] output_shift;

always @ (negedge SCL)

begin

if (lsb_bit)

begin

case (index_pointer)

8'h00: output_shift <= reg_00;

8'h01: output_shift <= reg_01;

// ... and so on ...

endcase

end

else

output_shift <= {output_shift[6:0], 1'b0};

endOutput driver

Finally, we’re ready to implement the output driver. We latch the output driver control signal to prevent bus glitches. The signal switches the driver between two states: high-impedance and pull-low. We pull low only under the following circumstances:

Acknowledging an address.

Acknowledging a master-to-slave transfer.

Transmitting a zero during a slave-to-master transfer.

The logic is a little subtle, because we have to set the state for

the next SCL clock cycle, taking into

account that the state machine’s state for the next cycle may not be the

same as what it is for the current cycle (note in particular the logic

for delivering the first bit of the first transfer in a read

transaction):

reg output_control;

assign SDA = output_control ? 1'bz : 1'b0;

always @ (posedge RST or negedge SCL)

begin

if (RST)

output_control <= 1'b1;

else if (start_detect)

output_control <= 1'b1;

else if (lsb_bit)

begin

output_control <=

!(((state == STATE_DEV_ADDR) && address_detect) ||

(state == STATE_IDX_PTR) ||

(state == STATE_WRITE));

end

else if (ack_bit)

begin

// Deliver the first bit of the next slave-to-master

// transfer, if applicable.

if (((state == STATE_READ) && master_ack) ||

((state == STATE_DEV_ADDR) &&

address_detect && read_write_bit))

output_control <= output_shift[7];

else

output_control <= 1'b1;

end

else if (state == STATE_READ)

output_control <= output_shift[7];

else

output_control <= 1'b1;

endSynchronization

It’s unlikely that a device will be clocked solely by

SCL. There will probably be other internal clock domains,

and the I2C interface must be able to transfer data to and from these

domains.

A two-phase REQ/ACK scheme is unsuitable in most cases due to the intermittent clock driving the I2C interface. However, since the device is likely being addressed by an MCU, software assistance on the part of the master can make the task easier.

Write synchronization

Provided data is not written more than once every few cycles of the other clock domain, a single-phase synchronization scheme is feasable. For each writable piece of data which must be synchronized, implement a data phase bit. Whenever the register is written, toggle the data phase register.

In the other clock domain, the data phase bit is sampled through a two-flop synchronizer. When a change is detected in the sampled data phase signal, the data in the I2C slave interface register can be latched into a register in the other clock domain.

This general scheme is fairly flexible, but other schemes may be possible, depending on the application. One simple scheme is to designate one bit in an I2C interface register to be an asynchronous reset for logic in the other domain, and require that software only change configuration registers while this reset is asserted.

Read synchronization

Since there is no minimum speed for I2C transfers, a data-phase toggle scheme as described above can’t be guaranteed to work correctly for reads. Instead, negotiation is required between the MCU and the internal logic via the I2C interface.

For example, one control bit in an I2C register may be designated a

“read-request” bit. This could trigger the internal logic to update the

data presented and set a “read-ready” bit. The read-ready bit can be

sampled through a two-flop synchronizer driven by SCL (this

is always possible for single bits). By the time the device has been

addressed, the state of the synchronized read-ready bit should be up to

date. At this point, the MCU can check the sampled bit and then decide

whether it’s possible to read the appropriate data register.

This scheme is a natural fit to reading the results of “one-shot” tasks. In many cases, the MCU will request a task to be executed by means of a control bit. It can then poll a status bit to be notified of task completion (with associated return data).

Caveats

This design uses both edges of SCL and SDA to drive flip-flops. For this to be safe, these lines must be glitch-free and they must adhere to I2C timing requirements.

If you’re taking these lines directly from the outside or via FPGA IO buffers without passing through any combinatorial logic gates, then you may assume you’re not introducing glitches that weren’t already present.

It would be a good idea to expose an asynchronous reset if your design is being driven from an externally-supplied I2C bus.